BME Wrist Pins: Incredible Strength. Utmost Durability

Tony Stewart won two NHRA Events in 2025 with the Mobil 1/MoPar Top Fuel Dragster. Stewart also clinched the 2025 Top Fuel regular-season championship. BME VascoMax Wrist Pins gave Stewart's engine the extra margin of reliability and durability needed to win. Image: NHRA

In a 12,000-hp, supercharged, nitromethane-burning drag racing engine, a wrist pin is one of its most highly stressed parts. Burning nitromethane rapidly expands in its combustion chambers, exerting tremendous pressure on the piston tops. Wrist pins transfer that pressure to the connecting rods. That load is a crushing, 65-tons. At 8400 RPM, that reciprocating, 130,000-pound load hits the pin 70 times a second.

Needless to say, wrist pins in a blown-fuel engine are subjected to high levels of bending and radial stress. Few raw materials have the high strength required by such extreme loading. Bill Miller Engineering Wrist Pins for Top Fuel Dragster and Nitro Funny Car engines are made of VascoMax C-300, a costly “superalloy” with the high strength, toughness, and durability necessary in a wrist pin for a supercharged, nitro application.

Developed in the early 1960s by the Vanadium-Alloy Steel Company for the U.S. Air Force and NASA, the Vasco-Max family of steel superalloys was first used in large, solid-fuel rocket motor cases. Today, Vasco Max alloys are used in a variety of aerospace, nuclear, industrial, and motorsports applications that require extremely high strength, toughness, and wear resistance.

In addition to the famed VascoMax Wrist Pin, the choice of nitro class racers, Bill Miller Engineering offers two other wrist pins for racing engines of various power levels.

Superalloy SPecifics

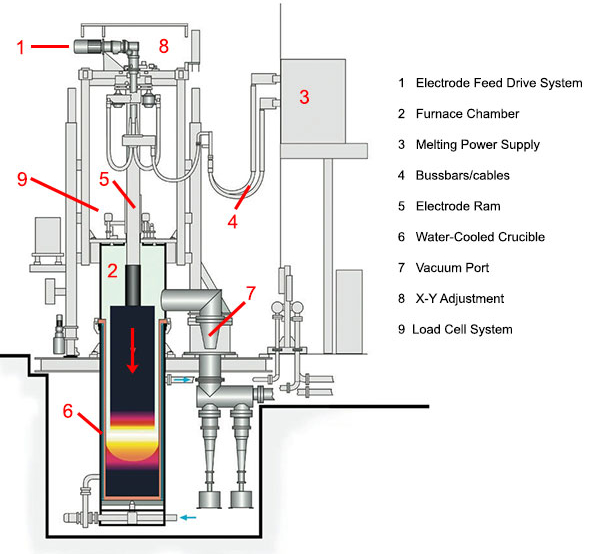

Vasco-Max C-300 is a low-carbon, nickel-cobalt-molybdenum steel alloy. It's smelted using the sophisticated "double vacuum melting" process. Step one is "vacuum induction melting" (VIM). That procedure takes place in an airtight refractory vessel, or "crucible", that is surrounded by a water-cooled, copper induction coil and is subjected to a vacuum. The metals to be alloyed are placed inside the vessel. It's sealed, and a high amperage alternating current is applied to the coil, creating a fluctuating magnetic field that induces eddy current flows inside the metals. That generates the heat that melts the metals. The vacuum prevents contamination resulting from the molten alloy reacting with the atmosphere and draws off gas bubbles. Once the alloy is blended, the electricity is shut off, the crucible is unsealed, then tilted. The molten metal flows into a "pouring box" and from there into cast iron molds, where it cools into ingots.

Step two is "vacuum arc remelting" (VAR). A C-300 ingot is placed in a different type of water-cooled, copper crucible. It's sealed and, again, a vacuum is applied to prevent reaction with air and to draw off bubbles. Then, a high-amperage, direct current is applied to an electrode inside the crucible. Arcing between that electrode and the ingot remelts the alloy. The molten alloy drips into a pool at the bottom of the crucible and, for a second time, hardens into an ingot having outstanding internal structure and excellent chemical homogeneity.

Lastly, the foundry puts the now superalloy through low-temperature heat treating. After that, the VascoMax C-300 ingots are hot worked into round bar stock. What makes this metal desirable as a raw material for Top Fuel and Funny Car wristpins is its very high ultimate tensile strength of 294,000 psi and an extreme fatigue endurance limit of one billion cycles at 125,000 psi. load.

This graphic is typical of a vacuum arc remelt furnace that produces the Vasco C300 bar stock used in a BME VascoMac Wrist Pin. Image: Carpenter Technology Corp.

The strength and durability of a BME Vasco-Max Wrist Pin come as much from the processes used to manufacture it as it does from its raw material. A section of Bill Miller Engineering’s Carson City, Nevada, manufacturing plant is equipped with CNC turning centers devoted solely to BME Wrist Pin production. The CNCs cut Vasco-Max C-300 bar stock into sections, precisely machine the inside and outside diameters, then cut the pins to length.

After CNC machining, to reduce the potential for stress cracking, BME applies a unique, mirror finish to the inside of each pin. The outside is finished by centerless grinding. Only a handful of companies in North America are able to manufacture wrist pins in this manner. As a result of the mirror-finished I.D., BME Vasco-Max Wrist Pins for nitro class drag race engines have an additional margin of reliability and durability.

VascoMax: The Nitro Racer's Wrist Pin Choice

Bob Tasca III a third generation racer who, back in 2013, was the first nitro Funny car in the threes. Oh yeah, he's won 15 National events, too. "BT3" demands performance and reliability, so he is a Bill Miller Engineering VascoMax Wrist Pin customer. Image: NHRA

Who's using Bill Miller Engineering's killer, VascoMax Wrist Pins in blown-fuel racing? Most of the big names in the sport, including: Twice NHRA Top Fuel Champion, Brittany Force, Austin Prock, who dominated the nitro Funny Car ranks in 2024 and 2025, four-time Top Fuel champ, Antron Brown, and Bob Tasca III.

John Force Racing has been a Bill Miller Engineering customer for about 50 years. Nitro class veteran, Jack Beckman, drives the Peak Antifreeze/JFR nitro funny car which, at the 2025 U.S. Nationals, was wrapped in a tribute to John Force's mid-70s era "Brute Force" funny car. Like those in all JFR race cars, Beckman's engine uses BME VascoMax WristPins. Image NHRA.

In Nitro Funny Car, BME's Vasco-Max Wrist Pins totally dominate the class. All of the 2025 Top Ten in points had them in their 12,000-hp engines.

Wrist Pins at 450 MPH - even 480

Obviously, the nitro class drag racers rave about BME's VascoMax Wrist Pins, but so do Bonneville record holders–and they go even faster.

Danny Thompson with the Challenger 2. It's two engines are fitted with BME VascoMax Wrist Pins. When he set the AA/FS record, he exited mile 5 at 459.588-mph. Image: ThompsonLSR

2018, BME Wrist Pins were in the engines Danny Thompson used to set a Bonneville speed record for non-supercharged, piston-powered vehicles. Southern California Timing Association (SCTA) National Records at Bonneville Salt Flats, Utah, are an average of two runs, one each direction. In each run, the car accelerates for five miles, with the last two of those five a speed trap. After that, there are two miles left to stop.

On 11-13 August 2018, Thompson set the SCTA AA/Fuel Streamliner National Record at 448.757 mph, driving the twin-engine, all-wheel-drive "Challenger 2". Powering the "C2" are a pair of 500-inch, Jerry Darien-built, Brad Anderson Hemis. Each is unblown on 87% nitromethane and produces 3500-hp. For the performance, reliability, and durability needed to produce a sustained 7000-hp for 5 miles, Danny Thompson uses BME VascoMax Wrist Pins along with BME Forged Aluminum Rods and Pistons. Danny's two runs were 446.605 mph and 450.909 mph averaging 448.757 At this writing in the Fall of 2025, "DT's" record still stands.

The front engine in the Challenger 2. Both Danny Thompson's 3500 hp Hemis use BME VascoMax Wrist Pins. Image: BME

The most storied car in modern Bonneville racing history is the "Speed Demon," which runs in the SCTA's top class, AA/Blown Fuel Streamliner. It's powered by a single, 555- inch, twin-turbocharged Big-Block Chevy on methanol. The Kenny Duetweiller-built Big-Block uses BME VascoMax Wrist Pins, BME Racing Pistons, and makes an astonishing 3156 hp at 8300 RPM.

13 August 2020: Speed Demon was push-started for the "Up" run on the five-mile-long course. A few minutes later, George Poteet averaged 470.733 mph in mile five and exited at an astonishing 481.576. The next day, starting at the other end of the course on its “Down Run”, Speed Demon did mile five at 469.298 and exited at 477.050. The two-run average was 470.015 mph, a new AA/BFS record. Eight BME Wrist Pins and Pistons helped Poteet set that record, a mark that still stands five years later.

The Speed Demon Team after setting the SCTA B/Blown Fuel Streamliner record in 2024. The late Chris Raschke's record came with the performance and reliability of BME VascoMax Wrist Pins. Image: Speed Demon Racing Team.

In 2023, the late Chris Raschke took over as Speed Demon Racing's driver and, the following year, set a B/BFS Bonneville record at 432.274 MPH. The "B-class engine" is a twin-turbocharged, 388-cuin Small-Block Chevy fitted with BME Vasco Max wrist pins, BME Forged Aluminum Pistons, and made 2663-hp@8800 RPM.

The records held by the Challenger 2 and the Speed Demon make Bill Miller Engineering Vasco Max Wrist Pins the fastest and finest wrist pins you can get.

Pair of Pins for up to 5000-hp

One of the quickest cars the Pro Mod category, Mark Micke's M&M Transmissions '69 Camaro, is powered by a Pro Line Racing, twin-turbocharged 540-inch hemi fitted with BME S7 Wrist Pins. This car makes 4780 horsepower...at the tires!: Image: Drag Illustrated

The second product in Bill Miller Engineering's Wrist Pin line is made from heat treated, AISI S7 chrome-moly tool steel. The BME S7 Pin is a less costly alternative to the Vasco-Max Pin and is ideal for the supercharged alcohol or gasoline engines used in the Top Alcohol classes and Pro Mod racing, where the power output is in the 3000-5000-hp range. S7 Tool Steel is BME's choice for its "mid-market" wrist pin product, not only because of its strength, but also its exceptional wear-resistance.

Inside a 4500-hp, turbocharged, Pro Mod engine, a force of 30 tons hammers each wrist pin about 70 times a second. According, Pro Line Racing, one of the top engine builders in Pro Mod and a long-time Bill Miller Engineering customer, a BME S7 Wrist Pin in one of their 540-inch, 8500-RPM Pro Mod engines gets changed every 4 or 5 rebuilds, which is about 200-300 drag strip passes. One reason to choose Wrist Pins from Bill Miller Engineering is this unmatched reliability and durability.

BME's entry-level wrist pin offering, the 9310 VAR Pin, grew out of Bill Miller’s interest in manufacturing a wrist pin that meets the reliability and durability challenges in racing engines used in many types of motorsport, but is a better value than other pins on the market. Since BME introduced the 9310 Wrist Pin 25 years ago, drag racers, along with road racers and stock car racers, have switched to them.

Bill Miller Engineering's "mid-grade" offering, the BME S7 Wrist Pin. Image BME.

The BME 9310 Wrist Pin begins with 9310 VAR steel, a raw material with the purity and strength necessary for wrist pins used in unblown or supercharged race engines making up to 3000-hp. BME's 9310 VAR is also more cost-effective than some of the more exotic alloys used by other manufacturers selling wrist pins to the "under-3000-hp" market.

Once 9310 bar stock arrives at Bill Miller Engineering, like the VascoMax and S7 Tool Steel Wrist Pins, the 9310 VAR products receive BME’s special manufacturing processing, which gives their I.Ds that distinctive, high-quality, mirror finish for which BME Wrist Pins are known.

With the Bill Miller Engineering Wrist Pin line, like BME Forged Aluminum Connecting Rods and Forged Aluminum Racing Pistons, aggressive pursuit of quality pays off with products that are reliable, durable, and perform beyond the expectations of the racers who win with them.