BME Rods Dominate Drag Racing

Why is the Bill Miller Engineering Forged Aluminum Connecting Rod the best on the market? Its quality, reliability, and durability. For 50 years, the BME Aluminum Rod has been the standard by which the rest are judged. No other maker of aluminum rods can say its product has been an industry benchmark for half a century.

November 2024 at the NHRA In-n-Out Burger Finals. Austin Prock is on his way to a stunning 3.828-341.68 in the first round of eliminations in the BME-equipped Auto Club Chevrolet. Prock would be the Funny Car runner-up in the event and the 2024 FC Champion. Image: NHRA

BME Aluminum Rods have won over 60 championships in nitro class drag racing. There's no better demonstration of the BME Rod's strength and reliability than the incredible streak of record-setting top speed numbers from John Force Racing that began at the end of the 2024 NHRA Mission Foods Drag Racing Series.

At the In-N-Out Burger Finals, Austin Prock, in the Auto Club/JFR Camaro, scorched Pomona Dragstrip's top end at 341.68 MPH, setting the NHRA top speed record for Funny Cars. Not only is the BME Forged Aluminum Rod the fastest in drag racing, but it also helped Austin win eight of the 20 NHRA National Events on his way to the 2024 FC Championship.

Connecting rods are one of the most highly stressed parts in a nitro class drag racing engine. Peak loading comes near the end of a 1000-foot pass. The "Prock Rocket", with Austin driving and Dad, famed crew chief Jimmy Prock, tuning, had consistent race-winning set-ups with engines making close to 12,000 horsepower. A key factor in Jimmy Prock's confidence to tune for 340+ MPH? The strength and reliability of Bill Miller Engineering Forged Aluminum Connecting Rods.

Then, we have Antron Brown. The long-time Top Fuel racer, champion in 2012, 2015, and 2016, won his fourth series title in 2024. Antron counted on crew chief Brian Corradi to tune the AB Racing Matco Tools Top Fuel Dragster for the performance and consistency needed to win six National Events on the way to the title.

2024 was a banner year for Antron Brown. He drove the BME-equipped Matco Tools/AB Racing Top Fuel Dragster to six event wins, including the In-n-Out Burger Finals, and he took home the '24 Top Fuel Championship. Image: NHRA

The strength and reliability of Bill Miller Engineering Aluminum Connecting Rods were one of the tools Brian used to give Antron a Championship-capable dragster at all 20 events in the 2024 Mission Drag Racing Series.

Other recent nitro class competitors who trusted BME Aluminum Connecting Rods? The 2018 and 2019 Funny Car Champions J.R. Todd and Robert Hight, to name a few.

How about Pro Mods? These very popular, highly modified door cars have gasoline- or methanol-burning engines that are supercharged, turbocharged, or normally aspirated with nitrous oxide injection. The top Pro Mod engines make upwards of 5000 horsepower. At NHRA National Events, they run a quarter-mile, but eighth-mile Pro Mod racing also has a much larger following, especially in the Midwest and Southeast.

One of the Pro Mods that is always one of the quickest and fastest is Mark Micke's M&M Transmissions '69 Camaro. Micke's bread-and-butter is eighth-mile racing. Mark holds the Midwest Drag Racing Series Pro Mod series record with a 3.556 at 229.94 and the World Series of Pro Mod record at 3.575/223.65. In quarter-mile testing, with Jose Gonzales driving, Micke's M&M Transmission car has run a 5.35 at 272.

Mark Micke's gorgeous, BME-equipped '69 Camaro Pro Mod. Image: Drag Illustrated

The engine in Micke's car is a 5200 horsepower, Proline Racing-built, 564-inch hemi with two Harts, 88-mm turbos. Mark relies on the strength and reliability of Bill Miller Engineering Forged Aluminum Connecting Rods as well as BME Pistons and Wrist Pins to get his gorgeous blue first-gen Camaro down the eighth consistently in the mid-threes at 220 miles an hour.

Where else do you see a lot of BME Aluminum Rods? Import drag racing. One of the quickest and fastest imports in the sport is Speed Factory Racing's all wheel drive Honda Civic. To date, its best drag strip pass has been a stunning 6.65-second blast. On a different occasion, the car trapped at an equally amazing 217.77 MPH. Bill Miller Engineering Aluminum Rods, BME Pistons, and BME VascoMax wrist pins are in the 2300-hp, Honda B-series, four-cylinder engine in the World's quickest and fastest all wheel drive import.

The BME-equipped, 2300-hp, 6.65-sec. Speed Factory Racing Honda Civic. Image: Speed Factory

It's one thing to win a few drag races and a season title or two, but it's a far greater accomplishment to be a consistent winner in a diverse range of drag racing classes for more than five decades. Other connecting rod makers may brag about racers who run their parts, but look at the facts–there is little doubt that BME Forged Aluminum Connecting Rods dominate drag racing.

BME at Bonneville

While Bill Miller Engineering Forged Aluminum Connecting Rods are quick and fast in drag racing, they've also made history going even faster at Bonneville Salt Flats.

Back in 1968, after setting Bonneville records in '59 and '60 with the four-engine "Challenger 1", famed land speed racer Mickey Thompson debuted an SOHC Ford-powered, twin-engine, all wheel drive car. That fall, the "Autolite Special" went 411 MPH one-way. Sadly, bad weather and poor course conditions ended the record attempt, and the car never ran again until Mickey's son, Danny, rebuilt it in the mid-2010s.

It was renamed "Challenger 2", the Ford "Cammers" were replaced with 500-inch, fuel-injected Brad Anderson Hemis. Each produced 2500-hp on 50% nitromethane and were built with Bill Miller Forged Aluminum Connecting Rods, Forged Aluminum Pistons, and VascoMax Wrist Pins. The BME parts provided the strength and reliability needed to produce 5000-hp for five miles and do it at least twice when attempting to set a record.

On 21 August 2016, Danny Thompson set the SCTA AA/Fuel Streamliner National Record at 406.769 mph. Three weeks later, he was back at Bonneville with the BME-equipped "C2" to try for a World Record in FIA Category A, Group II Class 11. Almost sixty years before, Danny's Dad set a 345.33-mph mark in the same class with the Challenger 1, powered by four injected Pontiacs on 40% nitro. Early morning, 16 September: running against an existing 414-mph record, Danny came oh-so-close. At 413 mph, both rear tires exploded, ripping the rear driveshaft out of the car and tearing up the body. Hopes for an FIA record were dashed.

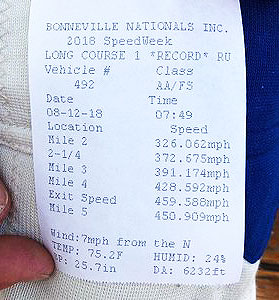

The Challenger 2 Team and their streamliner at Bonneville after setting the AA/FS National Record. In the front row, second from right is owner/driver, Danny Thompson. The time slip for the last run is below right. Images: Thompson LSR

On 11-13 August 2018, Danny Thompson took Challenger 2 to Bonneville one last time. Danny made two runs in the BME-equipped streamliner. For the 2018 runs, each engine was making 3500-hp on 87% nitro. Mile five for the first run averaged 446.605 mph. For the second, it was 450.909 mph. The two-way average was 448.757 mph, another new record in AA/Fuel Streamliner for Danny Thompson. At this writing, seven years later, that record still stands. Challenger 2 is now in a Northern California museum.

Be it an eighth mile, a quarter mile, or 5 miles, the BME Forged Aluminum Connecting Rod is the fastest and finest aluminum rod available on the market today–as it has been for the last 50 years.

Miracle Metal

Until 1995, Bill Miller Engineering Forged Aluminum Connecting Rods were made of 7075 aluminum, heat-treated to the T6 specification. In the early 1990s, Alcoa developed a new aluminum alloy, a derivation of 7075-T6, for the Boeing Company to use for the wing spars and other high-strength, lightweight structures in its military and commercial aircraft. In 1996, after a joint development program with metallurgists at Aluminum Precision Products Corporation, a specialty foundry in California, Bill Miller Engineering introduced connecting rods made of this new alloy. Compared to the older material, the BME/APP "Modified 7075-T6" had a 15% average increase in tensile and yield strength, equal or better elongation and other mechanical qualities, but, most importantly, no increase in weight. Rods made of Modified 7075-T6 offered racers higher strength and longer fatigue life from a part of the same weight.

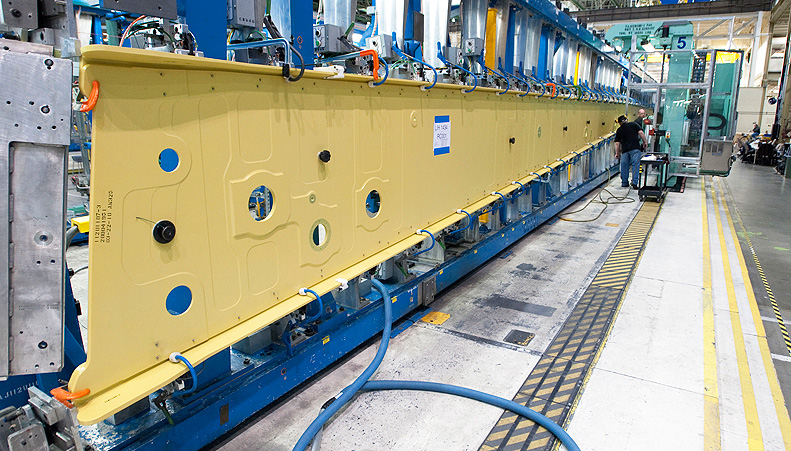

Obviously, Alcoa didn't invent a new aluminum alloy just for BME rods. The original application was for wing spars and other large aluminum structures in Boeing's commercial and military aircraft. There are three spars in a 747's wing. This is the center or "main" spar for the first 747-8, the latest version of Boeing's storied jumbo jet.

Image: Boeing Commercial Airplane Co

In 2010, after raw materials costs shot up during the 2000s, Bill Miller Engineering began researching materials and processes that would maintain the benefits and the value of BME Aluminum Rods. Once again, in cooperation with specialty foundry Aluminum Precision Products, BME introduced yet another new alloy, "Modified 7075-T6 2.0," for aluminum connecting rod applications based on what they developed fourteen years before. As always, when it introduces a new material, connecting rods made of it were tested, both in the lab and on the racetrack in BME's Top Fuel Dragster, to validate quality, performance, reliability, and durability. The result was BME Aluminum Connecting Rods that had the same strength, reliability, and durability as the 1996 design, but also held the line on value.

BME Beats the Billets

The Aluminum Association, a trade organization of primary aluminum producers that sets industry standards, defines a "billet" as a "hot-worked, semifinished product suitable for subsequent reworking." Other manufacturers sell "billet aluminum" connecting rods. Unfortunately, BME's competitors don't disclose that the billets they use are rectangular sections of extruded aluminum that are 12 feet long, 4.5 inches wide, and about 1.5 inches thick.

In this era of lightweight engine components, exceptional fatigue life comes only from superior raw materials, outstanding design, and modern manufacturing processes. Bill Miller Engineering has combined the outstanding metallurgy in its advanced aluminum alloy with the advantages of the die-forging process to produce a forged aluminum connecting rod that beats the rods cut from rectangular extrusions under real-world racing conditions. Proof of that is the number of Nitro Class drag racers who use BME Rods and the well over fifty championships in blown-fuel classes they've won since 1975. No other aluminum connecting rod even comes close to that record.

Today's demanding quality and productivity standards mean there's a lot of automation in the making of a BME Aluminum Rod. That said, to make the best aluminum rod in the world, still requires some of the manufacturing process to be done by hand by experienced craftsmen with sharp eyes and a fine sense of touch. The big and small ends of each BME rod are finished by hand on a Sunnen Rod Hone. Image: BME Ltd.

The Modified 7075-T6 2.0 aluminum BME uses to make its connecting rods is not available in the lesser-quality, 12-foot rectangular extrusions used by competitors. BME's raw material is aluminum bar stock, which has been subjected to a minimum 6:1 extrusion ratio. It's important to note that this extruded bar stock is, indeed, a billet, because it’s "a semifinished, hot-worked aluminum product." However, while an extrusion is the final form of the competition’s raw material, it’s only the start of a Bill Miller Engineering Rod.

Forged for Ultimate Strength

The first step in making a BME Forged Aluminum Rod, forging the Rod's basic structure from a chunk of aerospace-quality aluminum.

A half-a-dozen raw BME forgings. They'll sit for a while then get moved to the machining facility. Don't touch! They're still hot.

During Alcoa's early-1990s research into the strength of connecting rod materials, which resulted in BME's switch to a new type of aluminum, fatigue life studies proved failures are caused chiefly by stress resulting from severed grains and improper grain direction. Cutting a billet from a rectangular extrusion, then machining it into a connecting rod, severs grain ends. With critical sections of the rod, such as the tapered beam or the big end, those severed grain ends weaken the rod. In addition, if those uncut grains are not aligned in the proper direction, the rod's strength will be further degraded.

The BME-designed die-forging process that takes place at Aluminum Precision Products shapes the extruded aluminum bar stock and compresses its grain density by heating it to 700°F, then applying a pressure of 2000 tons. Compared to rods machined out of ordinary rectangular extrusions, Bill Miller Engineering's forging process: 1) enhances grain flow and increases grain density, 2) forces the grain of the extrusion into the connecting rod shape without exposing grain ends, 3) aligns that part of the grain which makes up the rod's tapered beam with the direction of highest stress the rod will sustain, and 4) forces the grain around the rod bearing bore, creating a "hoop stress" phenomenon which provides maximum strength for the limited cross-section available at the rod’s big end. These qualities are impossible to attain with connecting rods carved out of rectangular aluminum extrusions. Those advantages are also why a BME Forged Aluminum Connecting Rod has an exceptionally long fatigue life.

BME Rods are available in a variety of architectures, such as Chrysler 426 Hemi, 440 Wedge, and 340 A-Block, Chevrolet Small- and Big-Block V8s, Ford V8s, and traditional Pontiac V8s. Bill Miller Engineering can custom-make aluminum rods for virtually any engine. Past custom connecting rod projects were for a Mercedes V8, a 1925 Mercer Raceabout six-cylinder, a Nissan DOHC V6, and a single-cylinder speedway motorcycle engine. For more information, see our rod prices page or call BME for pricing on custom work.

The Only Streetable Aluminum Rod

Urban legends abound in the gearhead community. One is: aluminum connecting rods don't work in street engines. Prior to the mid-'70s, that might have been true; however, the introduction of the Bill Miller Engineering Forged Aluminum Connecting Rod in 1975 discredited that myth.

The BME Rod has great durability in very high torque output, street/strip, or hot street engines because it is die-forged. Plus, it's unique, BME-derived, modified 7075-T6 aluminum alloy further enhances fatigue strength such that the durability of BME Rod rivals that of many forged steel rods and exceeds that of a few.

About 40 years ago, a resourceful engine builder named Ken Crocie experimented with BME Rods in very high-performance street engines. Crocie, a Pontiac V8 specialist, faced with a shortage of acceptable steel rods for modified engines, tried BME rods and had great success. Although a few other engine builders followed Crocie's lead, admittedly, use of the Bill Miller Engineering Rod in street engines has not been widespread, because of the stubborn belief that any aluminum rod is unsuitable for street use.

"You'd be surprised at how many calls and emails we get asking about our aluminum rods in high-performance street or street/track engines," BME President Bill Miller said in an interview with an automotive magazine. "In a hot street application, using the aluminum rod is a no brainer, I don't know how the myth that aluminum rods can't be used on the street got started, but I'll guess that, back in the day, they weren't making them using the process we're using today.

"With the special material we use," Miller continued, "and the way we manufacture the connecting rods, they'll live 100,000 miles on the street because, compared to some of the racing applications in which our rods are used, a street application is, for the most part, low load. For example, our basic Aluminum Rod for the traditional (Gen 1 and Gen 2) small-block Chevrolet is designed for 1000-hp and 10,000 rpm. That rod is way overkill for the stress it will undergo on the street. We have been selling aluminum rods for high-performance street use for more than five decades."

Why build a street engine with BME Rods? One reason is the "cool factor." Bill Miller Engineering Rods are unique, high-end racing parts, and there will always be people who spend extra money to have the same rods in their engines that nitro class engine builders use. More importantly, there are practical reasons for using BME Rods, the same reasons racers use them: less reciprocating and rotating mass due to their comparative lightness. That allows the engine to accelerate more quickly. Lighter rods also improve throttle response and allow the engine to run reliably at a higher rpm than it could with steel rods.

A few things must be done differently when setting up a street engine for BME Rods. Minimum bearing clearance at room temperature should be .002-.0025-in. Wrist pin clearance should be .0006-.0008-in. Rod side clearance should be .018-.030-in. The engine's oiling system needs to be appropriate for larger rod bearing clearances once the oil reaches operating temperature. The oiling system must be configured to provide 10 psi, hot oil pressure for every 1000 rpm in the engine's rpm range. The minimum acceptable oil is a premium, 10W40 synthetic, and Bill Miller Engineering recommends Red Line 10W40 Engine Oil.

Standard BME Forged Aluminum Connecting Rods for most Chevrolet, MoPar, and Pontiac V8s are reliable replacements for stock, forged steel connecting rods in engines of up to 1000 horsepower. Aluminum Rods for some Ford V8s of similar power output are available on special order. A Big-Block Chevrolet style aluminum rod BME makes for Pro Stock drag racing is, good for 1500-hp, is also available. If the application is a Chrysler 426 Hemi or big-block wedge, BME's blown-alcohol rods can be used at levels over 4000-hp with outstanding reliability/durability.

What About Cap Screws?

BME Aluminum Rods are assembled with two cap screws. Some racers call them "rod bolts," but that is incorrect. A bolt has a flat end, no washer face, and is manufactured to less stringent specifications. Rod bolts are installed into the rods, and the rod caps are pushed over them. Finally, nuts are threaded onto the bolts and torqued to specification.

Cap screws have chamfered ends, ground flat washer surfaces under the bolt heads and are manufactured to tighter tolerances. Each has a hardened, flat washer with ground surfaces and a chamfer on its inside diameter to clear the fillet where the bottom of the head meets the shank. BME Aluminum Rod cap screws are installed and tightened by turning their heads with a 12-point socket.

ARP 2000 steel, rolled threads and a special, BME-designed heat-treating process makes the cap screws in a BME Forged Aluminum Connecting Rod the strongest in the industry. Image: BME Ltd.

Keeping with Bill Miller Engineering's steadfast commitment to quality, it installs nothing but the finest cap screws in its Forged Aluminum Connecting Rods. These fasteners are manufactured to BME's specifications by the world's top fastener manufacturer, Automotive Racing Products (ARP). BME/ARP cap screws come in three varieties.

BME/ARP 2000 rod bolts are mounted in vertical racks during the heat-treat process. Vertical racking insures 360-deg. thermal penetration by the heat-treating process. Image: BME Ltd.

A rack of BME/ARP 2000 cap screws gets pushed into the heat-treating oven at ARP's in-house, heat-treating facility. Yep. It's hot in there. How hot? Well, that's a trade secret, but we can tell you it's well over 1000 degrees F. Image: BME, Ltd.

Fastener Care

Most BME Aluminum rods use fasteners made of 8740 chromium-molybdenum steel, a quenched and tempered steel alloy having a yield strength of 180,000 psi and tensile strength of 200,000 psi. These fasteners have an excellent margin of strength for most aluminum connecting rod applications. The 8740 cap screws should be tightened to 75-foot/pounds.

Cap screws used in rods Bill Miller Engineering makes for engines that are supercharged, turbocharged or use nitrous oxide and have a limit of 9000 rpm are made of a special hybrid alloy, "L-19." Fasteners made of this ARP-developed material receive a BME-proprietary, heat-treating process designed specifically for connecting rod cap screws for applications using power adders. BME L-19 fasteners have a yield strength of 220,000 psi and a tensile strength of 260,000 psi. That additional strength results in up to a 25% increase in clamping force. BME L-19 cap screws are available in two thread sizes: the "standard" SAE 7/16-20 and an optional, 12-mm x 1.25-mm which is perceived as better for blown fuel applications. L-19 Cap screws on Bill Miller Forged Aluminum Connecting Rods should be torqued to 100-125 ft/lb depending on application. Before ordering, contact BME for application-specific torque information.

The BME rods used in the most severe supercharged alcohol and Pro Mod applications are subjected to the highest stress. Those engines run as much as 11,000 rpm. Loading on connecting rods is mainly dependent on engine speed. At 11,000 rpm, at top dead center on the exhaust stroke, the inertia load is about 13½ tons. To maintain rod cap clamping pressure, Bill Miller Aluminum Rods for high rpm blown alcohol or Pro Mod engines use an even stronger cap screw that ARP makes out of "Custom Age 625+" a steel "super-alloy." Its specifications are amazing. Its yield strength is 255,000 psi, and its tensile strength is 280,000 psi. CA 625+ fasteners must be torqued to 125 ft. lbs.

BME/ARP fasteners are manufactured at Automotive Racing Product's Santa Paula, California facility using SDF or CHQ grade, both better than "aircraft grade," raw materials. To ensure complete, 360-degree heat penetration, they are heat-treated in vertical racks. Like all ARP cap screws, the fasteners in BME Rods have rolled threads and the thread rolling is done after heat-treating which provides up to 20-times more fatigue life than cap screws having threads rolled before heat-treating.

The unique alloys used in BME/ARP cap screws are susceptible to varying levels of corrosion–even sweat will cause problems–so they require special care. Before use, normally, you only need to blow them off with shop air; however, the air compressor must have a moisture trap. If a moisture trap is not installed, use "canned air" available from hardware vendors. If washing is necessary, do that only with a solvent-based cleaning process then dry the cap screws with shop or canned air.

Once cap screws are blown clean or dry, immediately fill a small tray with oil and submerge the fasteners. Leave them in oil until you are ready to install them. Leave the cap screws coated with oil during the installation process. Never allow them to dry.

There are also special procedures for storing cap screws in BME Aluminum rods. To prevent stress corrosion, do not store BME Rods with the cap screws torqued to specification. They must be stored with the fasteners well-oiled and finger-tight.

BME Rods: The finest money can buy

Four reasons to choose BME Rods:

- They outperform and outlast all other aluminum connecting rods.

- BME has rigorous manufacturing process controls.

- In 50 years of manufacturing aluminum connecting rods, Bill Miller Engineering has a reputation for innovative technology and continuous improvement.

- Bill Miller Engineering Forged Aluminum Connecting Rods are made in America with 100% U.S.-sourced materials. They have the best workmanship of any racing connecting rod on the market today.

If you need more information before placing a BME Aluminum Rod order, call us and ask for Bill.

What's great about BME is the hands-on involvement of company President, Bill Miller, at left. Bill started BME with the Forged Aluminum Connecting Rod as his first product and he was the company's only employee. Today, 40 years later, Miller is still involved with design, development, manufacturing and marketing the entire process. He works directly with his team members and deals with many customers personally, such as 16-time Funny Car Champion, John Force, shown below, talking with Bill at the 2011 NHRA Winternationals. Images: BME Ltd.

Since 1975, Bill Miller Engineering has been dedicated to designing, developing, and manufacturing the finest aluminum connecting rods in the industry. Our commitment to the racer is total. We conduct continuous research and development to increase the performance and improve the reliability of our product. Rest assured, when you buy BME Forged Aluminum Connecting Rods; you get the best connecting rod modern technology can provide.

Bill Miller stands behind his company’s rods, both literally and figuratively. The BME Forged Aluminum Connecting Rod was Bill Miller’s first product and remains the core of his business.